Our Processes

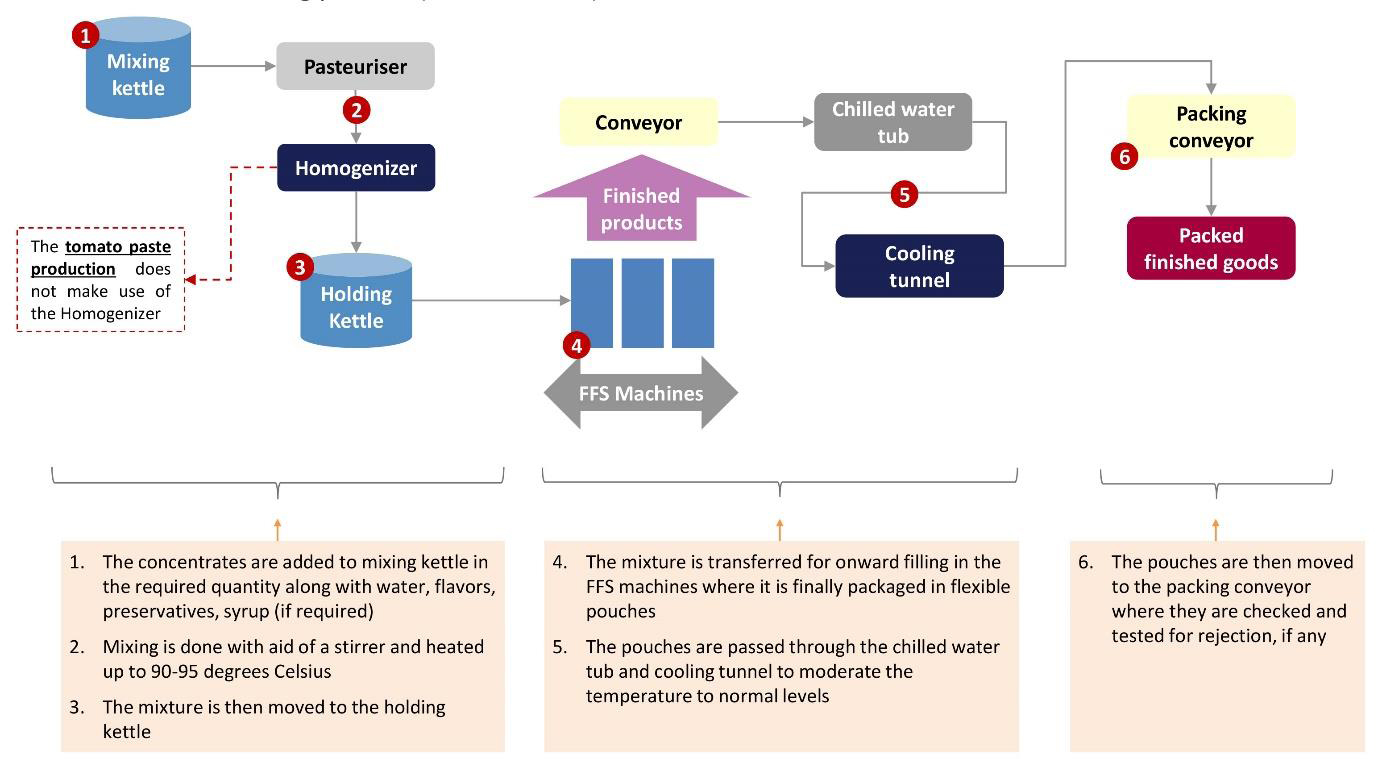

Manufacturing processThe Company’s manufacturing facility certified by the SON and NAFDAC comprises state-of-the-art form, fill and seal machines for beverages, tomato products and ginger/garlic pastes. The factory’s flexible packing capability and quick-freezing technology reduces prices and minimizes risk of food contamination.

Packaged Foods

All pastes are thoroughly weighed in an enclosed but ventilated area. Mixing is done with the aid of a stirrer and transferred to the holding tank and heated up to 90-95 degrees celsius. The prepared paste is fed continuously via the filling machine tank to hot pouches which pass through the conveyor to the coolers.

The cooled pouches pass through the air blower to dry, are packed into cartons and transferred to the warehouse.

Seasoning

All raw ingredients are weighed in an enclosed but ventilated area. The prepared seasoning is fed via the filling machine tank to pouches which pass through the conveyor to the coolers.

The cooled pouches pass through the air blower to dry, are packed into cartons and transferred to the warehouse.

Beverages

The weighing of liquid raw material is done in an enclosed but ventilated area. Sugar and treated water are mixed into a syrup and steam boiled to 80-85 degrees celsius.

The beverage is then passed through the beverage tank and is fed continuously through the filling machine tank to a hot pouch. The pouches are then passed through the coolers to the air blower to dry, packed into cartons and transferred to the warehouse.

Factory Process

The End Results